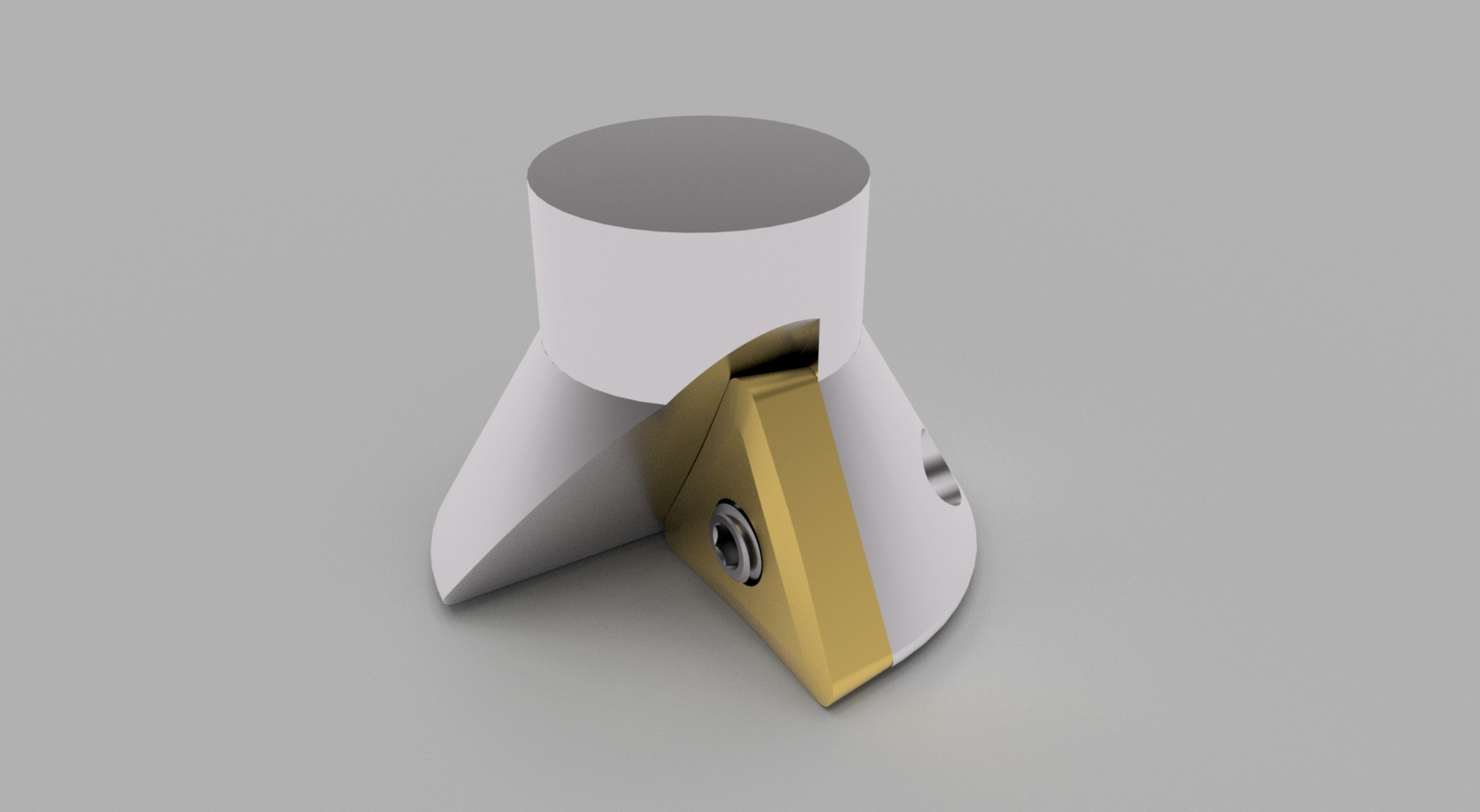

For my Tripan-toolholder-project i needed a 60° dovetail cutter. I got one which worked really great with the prototype:

After inspecting the work and the tool, I saw a beginning wear in the tool. Those tools are to expensive to get them stub after 2 or 3 parts. So, I thought about an indexable tool – but they are even more expensive than the solid ones! Consequence: make an own one.

There are a lot of people having done such a tool and published some infos on the web. I’ll put some links at the end of this post. They helped me out with some important informations (clearing of the insert for example).

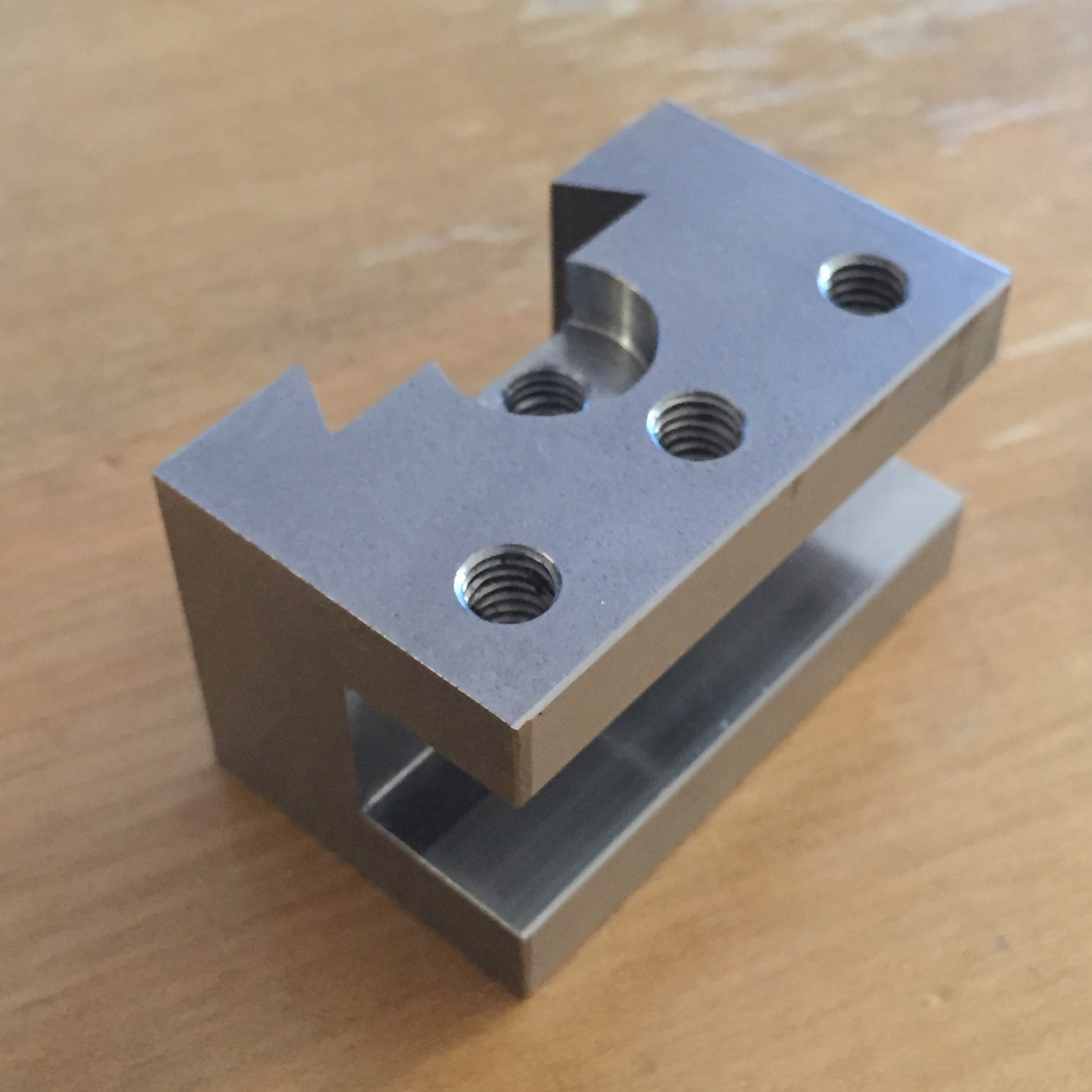

I start with the 2D in Fusion 360 of course – TCMT-Inserts seem to be right. Some measurements were given by the tool dimensions (1102XX), others I wanted to reach for the part which’d be milled. Take a closer look: a little clearing on the side and the bottom is already defined (0.25 mm)

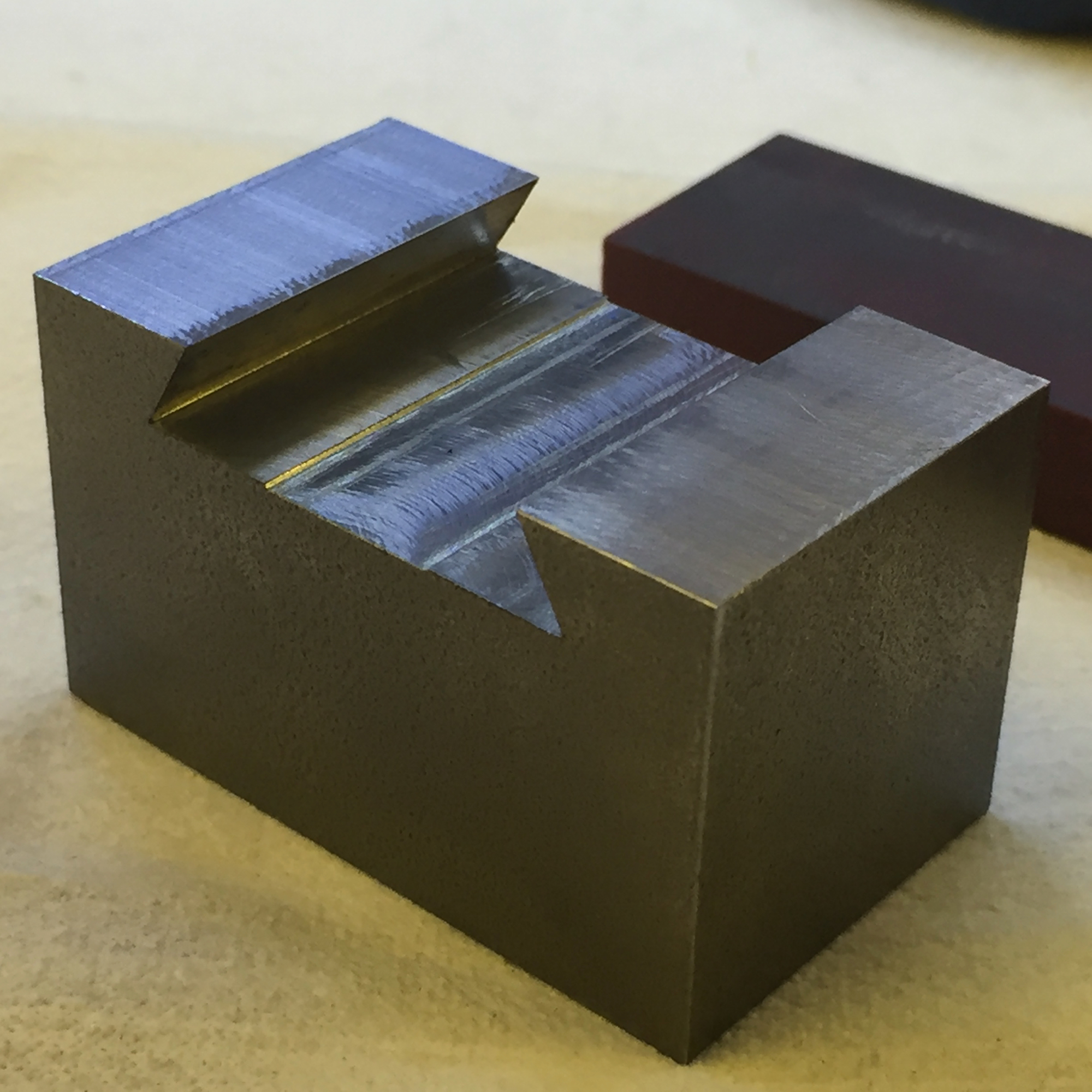

That’s the easy part. Now making some chips: stainless steel 20 mm rod first turned the shaft, after that the 60° angle and finally turning it down to lenght.

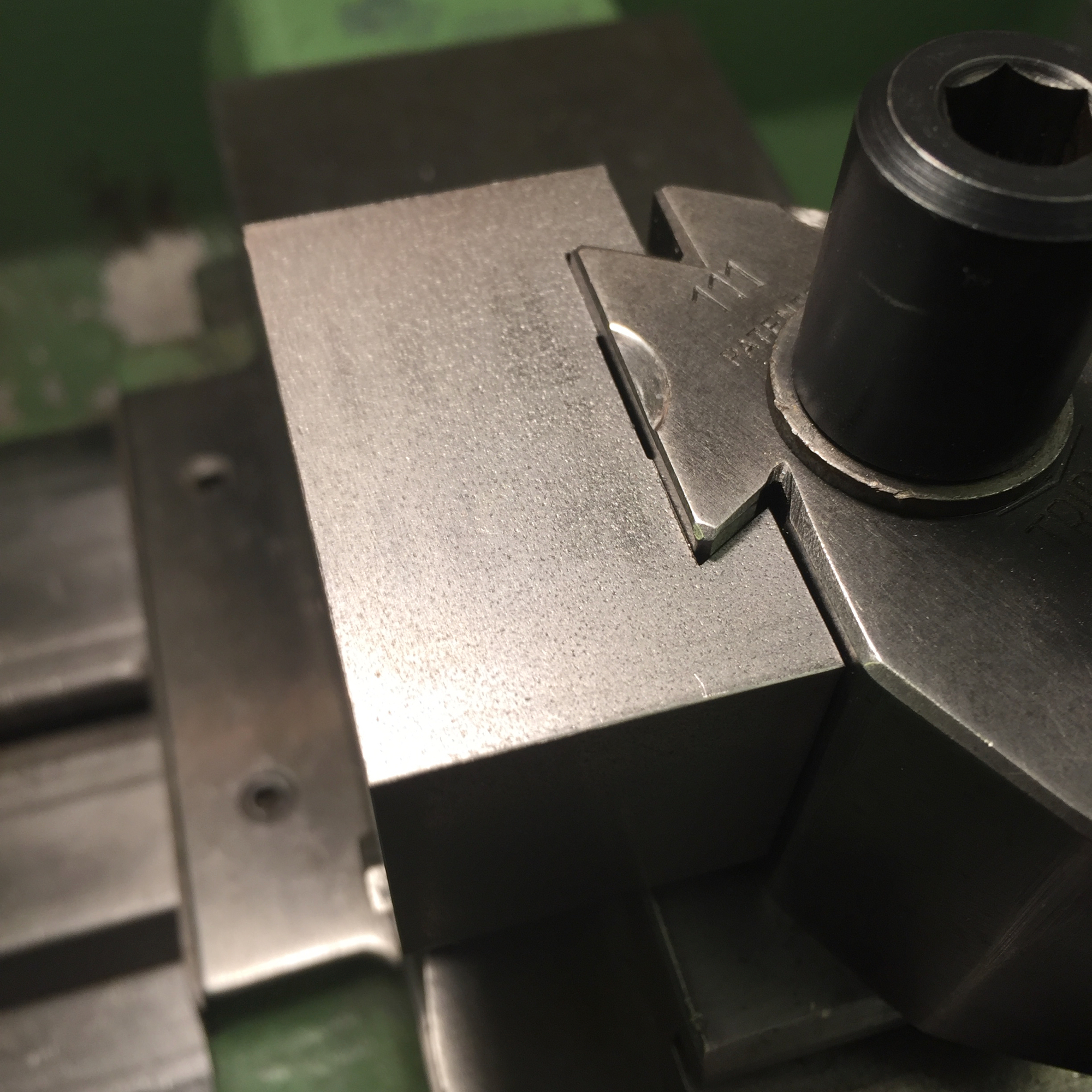

Holding it in a 5C-Collet-Block, the part was indexed in on the Tormach PCNC440. The height is no big deal – if the insert gets to high, I can still take another cut in the lathe to shorten it out. But to hit the centre is quite important. Here it’s not as simple to recover from a mistake. The CAM: roughing, finishing and making the hole in one step – so it’s already on the right place (if the CAD is correct, of course).

Well, yeah. That’s the result:

I’m really satisfied how it works and which performance you can get with it. I’m still testing and finding the right speeds and feeds. But of course I testet it on (my) edge: DOC 5 mm, WOC 1 mm at 5000 RMP in mild steel is no problem – even with high feedrates. To fast for me – but if you need to take roughing steps in a hurry…

The links:

- on CNCCookbook: some interesting infos – and of course the workflow

- on Youtube from Randy Richards

- on Youtube a review about those cutters from ChrisB257

Thanks to all of them. You helped me making this great tool!