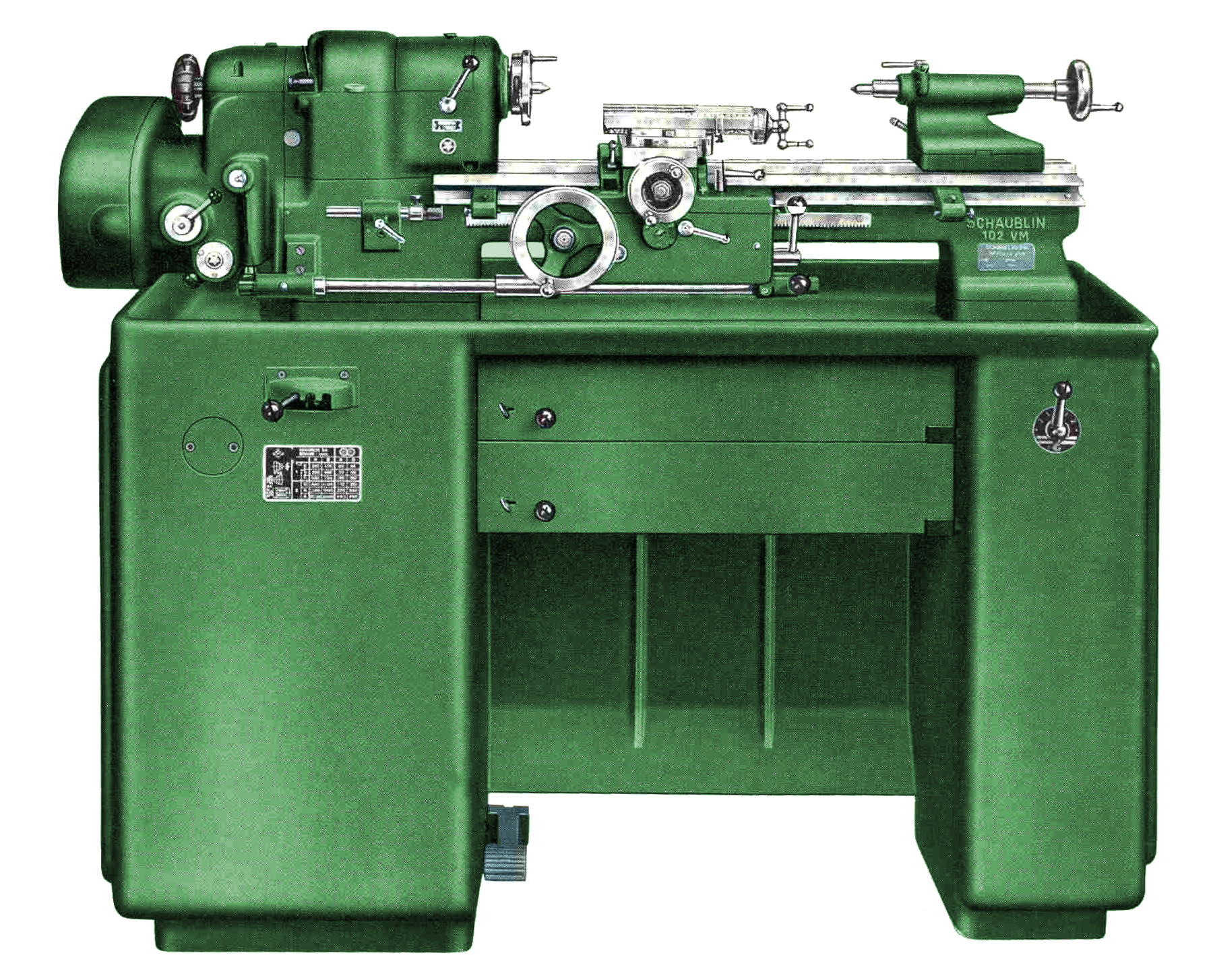

Technical Details

| Voltage | 380 V, three phase single voltage |

| Centres | Height: 102 mm, Distance between: 450 mm |

| Speeds | from 40 (with reduction gear) to 3000 RPM |

| Motor | Two speed motor with a foot operated clutch and brake and a knee operated direction lever |

| Headstock | W25, back geared, lever operated quick-closing attachment |

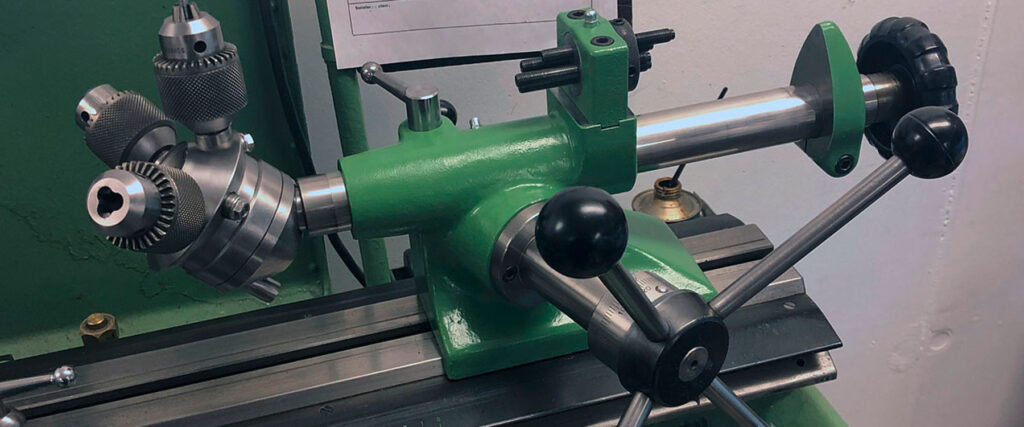

| Tailstock | W25 with MK2 Adaptor |

| Gear box | Two mechanism: one for power feed, one for screw cutting. All 26 pieces of the gears present |

| Colour | Original NCS S B7005-80G |

| Specials |

Massive cast iron stand with chiptray and two drawers |

| Weight | about 650 kg net |

History

The Schaublin 102VM was produced from 1930 to the mid-70’s (after that, the 102N-VM with the quite «bulky» design was launched). There are a lot of sites where you can gather more information about this machine – take an eye on the links at the bottom of this article…

Background

I found this Schaublin on an auction for a reasonable price April 2017. A lot accessories were onboard – other tools and addons were added later (some of them mentioned on Insta or on this blog). The images of the machine uploaded on the auction:

About that machine

This one’s my favorite – a real gem and a glutton for work!

I could have obtained a newer Schaublin (even for less money), but I really liked the «tubby face» of this machine. Blessed in disguise: working with this machine and handling delicate parts is a joy – no hard corners, no scrapes… 😛 The range this machine can handle is huge (at least in my terms). The range of workholding possibilities, the ratio of the motor, the dimensions fit my needs. Not more to say about that…

The headstock holds W25-Collets with a quick-closing lever (handy for run production). Those collets range from 0.3 mm up to 132 mm and are segmented in four different types, according to the closer used. They are available in different shapes (e.g. square) and forms (e.g. copped). This type of workholding is very repeatable and accurate – in combination with the lever and a depth stop you really can achieve quite precise production runs.

Of course, beneath all the inline W25-Collets, there are collets holding the workpiece on an inside diameter, or all typically known lathe chucks (x-jaws, magnetic chucks or the like).

holding the workpiece in the inside, and of course all kind of lathe chucks.

Related Posts

Links

Schaublin History on Anglo-Swiss-Tools

Schaublin 102VM on Anglo-Swiss-Tools

Schaublin 102VM on lathes.co.uk