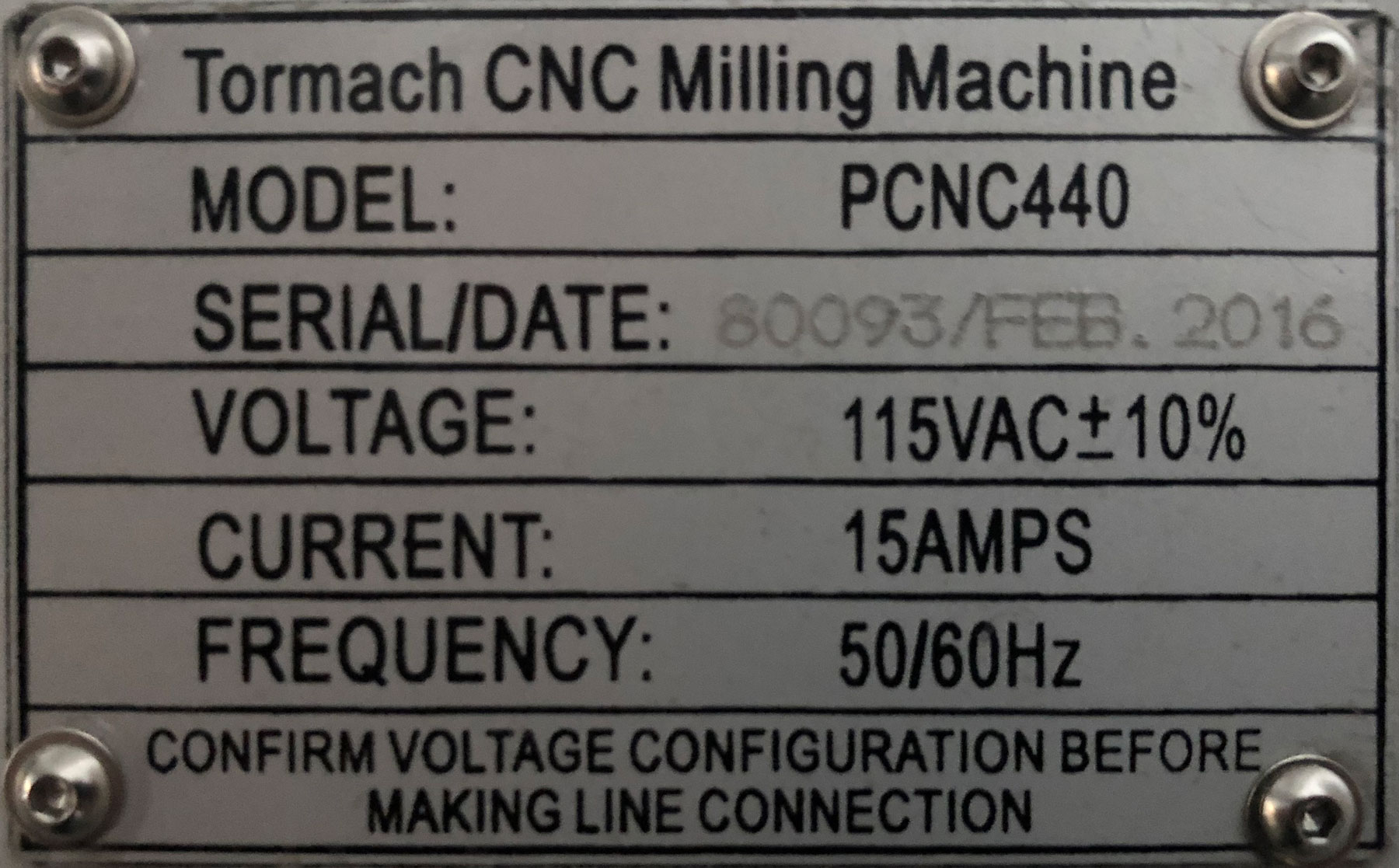

Technical Details

| Spindle |

0.56 kW (¾ hp), R8 with V-Belt Transmission |

| Speeds |

10’000 RPM |

| Table Size |

457 x 160 mm (18.0 × 6¼ in) |

| X-Axis |

254 mm (10 in) at 3.4 m/min (135 ipm) |

| Y-Axis |

160 mm (6¼ in) at 3.4 m/min (135 ipm) |

| Z-Axis |

254 mm (10 in) at 2.8 m/min (110 ipm) |

| Specials |

- Power Drawbar (with mod)

- Fogbuster (MMS)

- Full enclosure

|

| Weight |

about 270 kg net |

History

The history behind this machine is quite recent (well 2016 in fact is). But perhaps, the idea behind this machine can be of use for some people: the first CNC-machine I owned was a 3040 gantry-type machine. It worked with Mach3 and it was really fun to work and play with.

The limits of such a machine are obvious: it has quite a small footprint and the rigidity is more something for non-ferrous materials.

I was looking for a rigid, not too small and not oversized CNC-machine

TBC…

Related posts

Simple but convenient – tool organisation for the tripan toolholders! This is what it looks like at the end of

This one is from Mikes workshop site. I think he did a really great job, so I won't comment it

The idea of easing up the setup of the blade alignment is really delightful. I saw this or similar mods

Inside the gearbox, everything looked nice: no worn gears, just a tiny amount of play. I did open this already

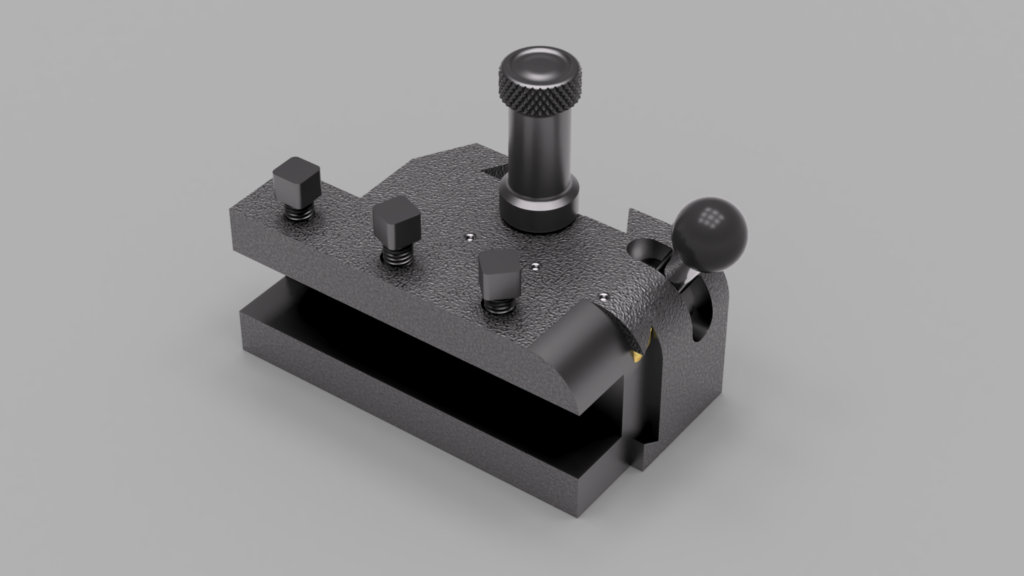

I really liked the idea of Jim Schmitt (on a post here) about the «inverted» retractable threading tool. Based on

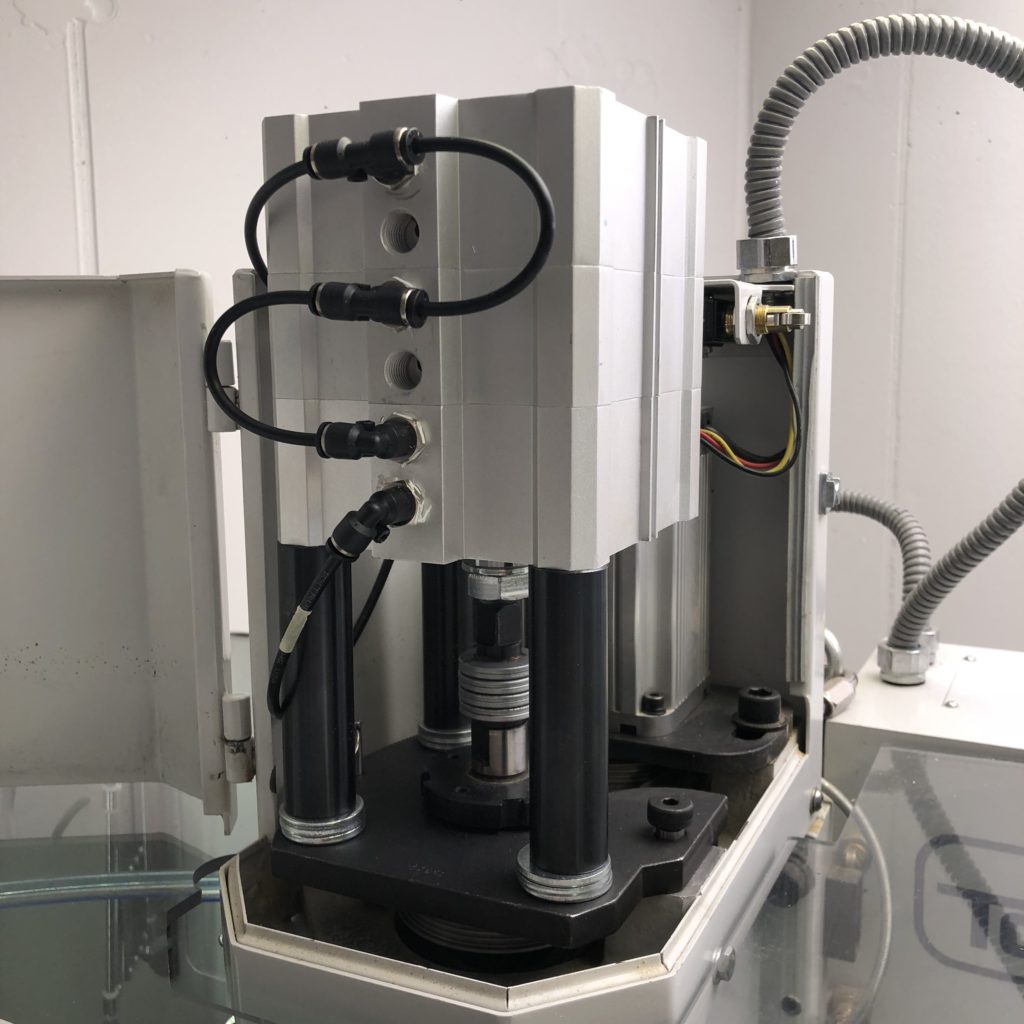

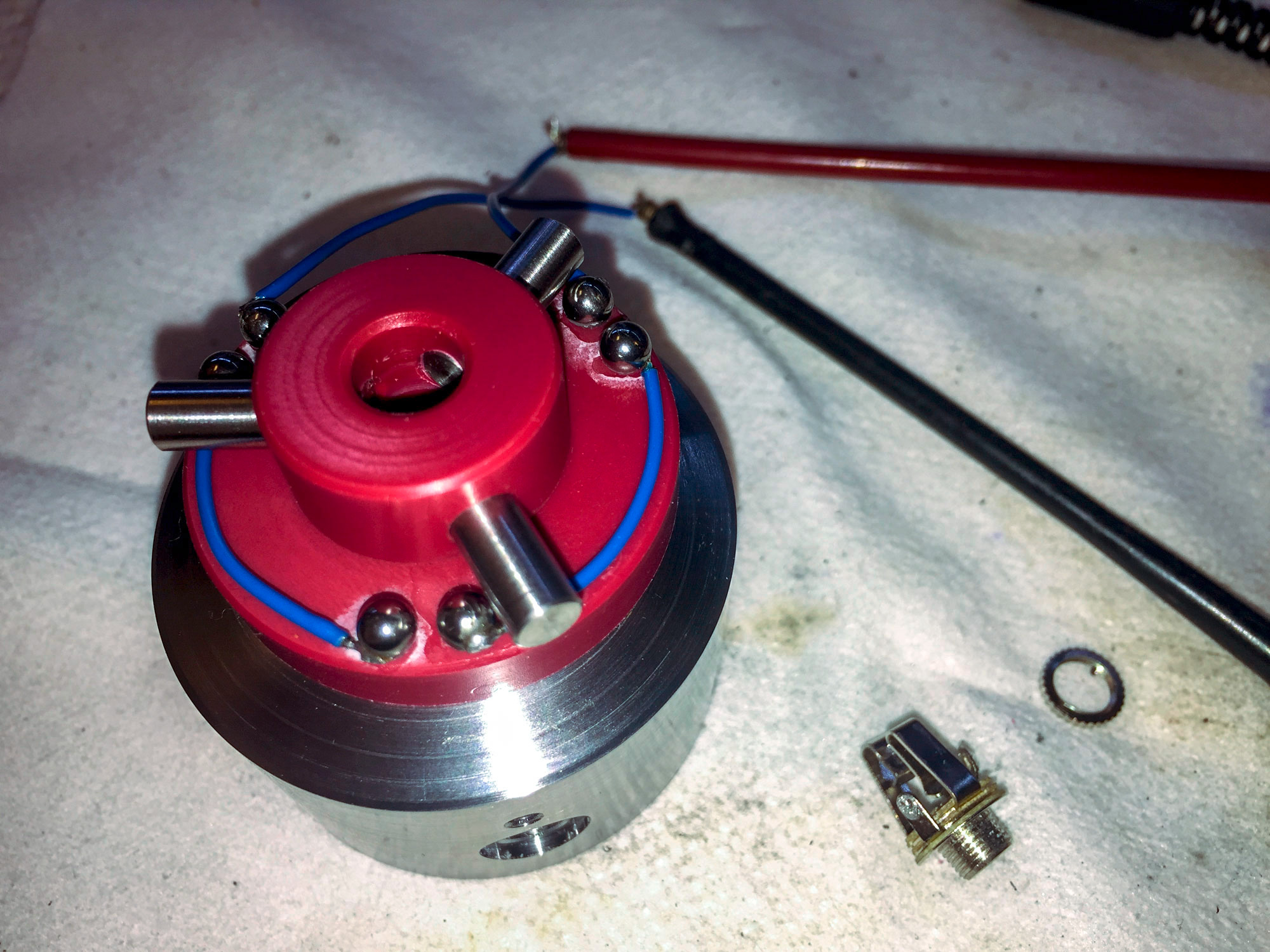

The power drawbar is a great add-on for the PCNC440. It eases the toolchange – which can get quite annoying

I have a Tripan toolholder system on the Schaublin-102VM lathe. It's an «old school» quick change system with adjustable height

For some work, a touch probe appeas to me as the right approach. The most obvious here is the indexing

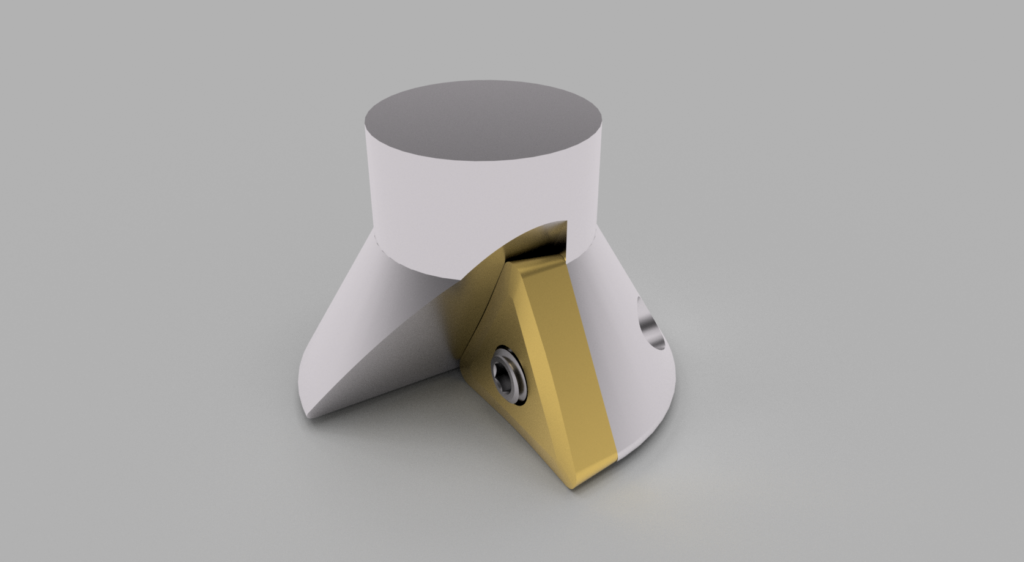

For my Tripan-toolholder-project i needed a 60° dovetail cutter. I got one which worked really great with the prototype: After

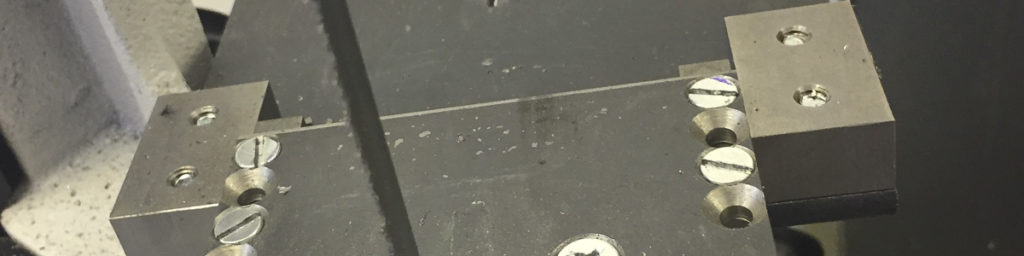

Today a big TTS collet holder was created. I wanted them to be safe and out of the way as