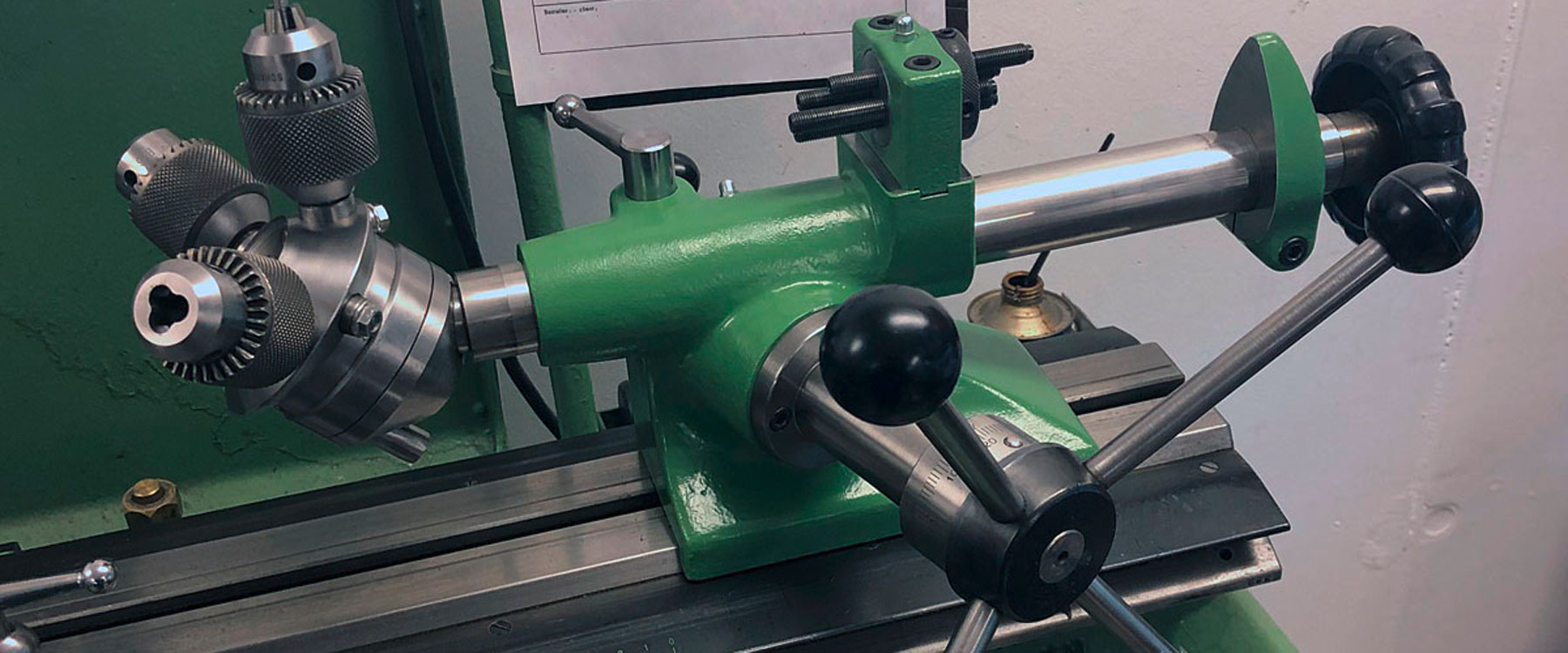

I wanted a starwheel tailstock for a long time – and finally got one on a company liquidation. It was not in a good shape, but I like a lot to refurbish this kind of tools.

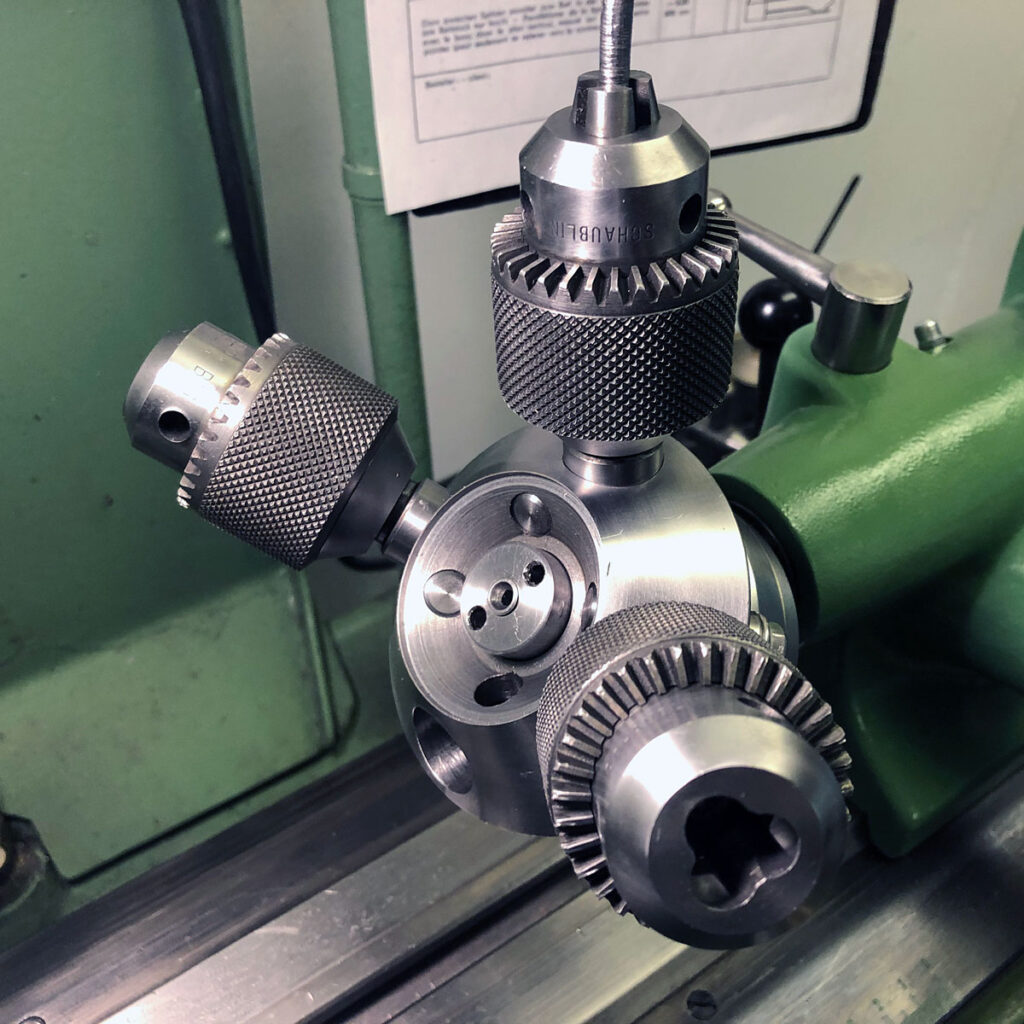

The toolchanger is mounted on a W20-collet and had some problems: it was sloppy and had some broken parts (which I don’t know how they are named officially).

It’s the part where the tool/toolholder is clamped. The clamping force is obtained by thightening the screw on the top of the part. Two of those screws had ruined threads, one was broken off completely! I think this happened to somebody, who didn’t know about the function of this clamp – but I have to admit, that I’ve also never seen this kind of clamping by pushing a rod upwards…

After disassembling and cleaning the whole tool, the same old steps again: sanding off the old paint, priming, filling, sanding and painting again. This time without the indulgence of a sandblaster (really a lot of handwork).